Best Practices for Data Logging During ECU Tuning Sessions

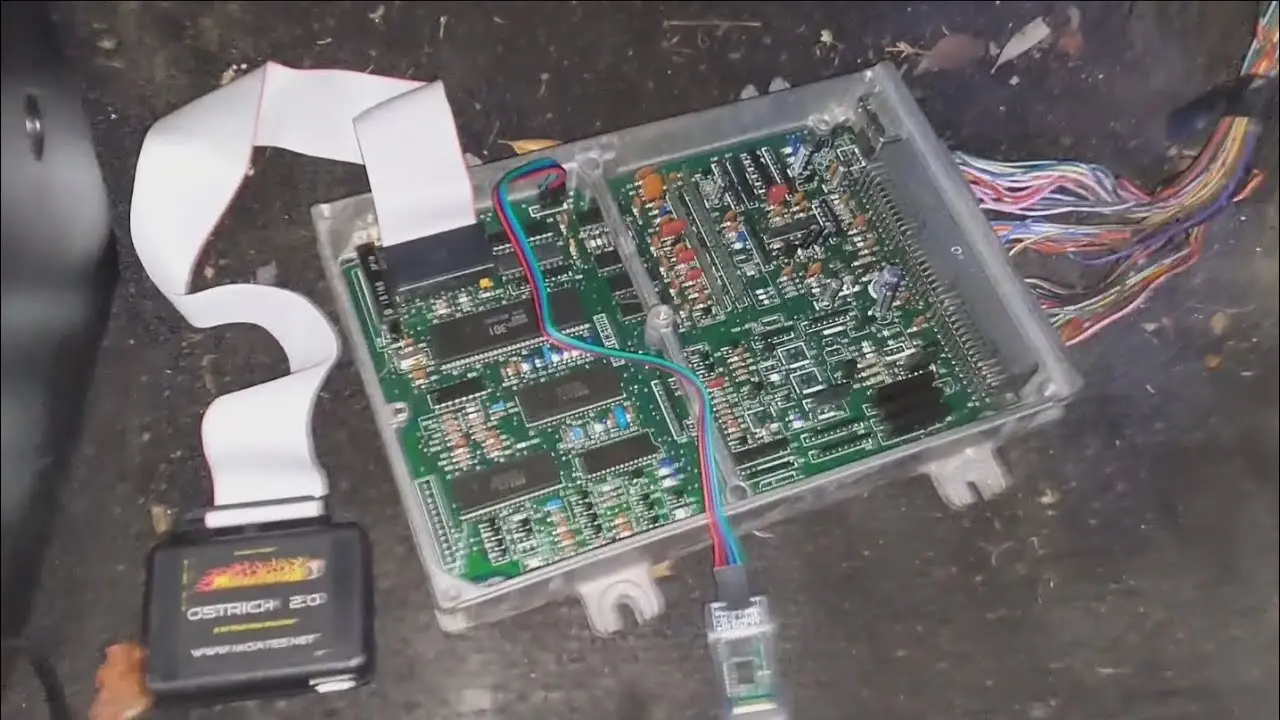

Engine data logging is absolutely crucial for effective ECU tuning. This guide covers best practices for data logging, including which parameters to monitor and how to interpret the data. Gather the information you need to make informed tuning decisions. This meta description encapsulates the core of what we’ll be diving into – how to get the most out of your data logging sessions when tuning your ECU.

Why Data Logging is Your Best Friend for ECU Tuning

Think of data logging as your engine's confessional. It spills all its secrets – well, the measurable ones anyway. Without it, you’re basically tuning blind, guessing at what's actually happening inside your engine. Data logging lets you see, in real-time (or as close to it as possible), how your changes are affecting various engine parameters. This is especially vital when you're pushing the limits with performance upgrades or custom ECU maps. It's the difference between cautiously exploring the performance envelope and potentially grenading your engine.

Key Parameters to Monitor During ECU Tuning: The Essentials

Alright, so what should you actually be looking at? Here's a rundown of the essential parameters to monitor during your ECU tuning sessions. These are the bread and butter of data logging, and understanding them is key to successful tuning:

- Air-Fuel Ratio (AFR) or Lambda: This is the big one. AFR/Lambda tells you how much air is mixed with the fuel being burned in your engine. Crucially important for power, efficiency, and engine longevity. Target AFRs vary depending on your setup, but generally, you're aiming for something around 14.7:1 for cruising (stoichiometric), and richer (lower numbers) for power under boost or high load.

- Manifold Absolute Pressure (MAP) or Boost Pressure: For turbocharged or supercharged engines, MAP or boost pressure is critical. You need to know how much boost you're actually making and ensure it's within safe limits. Overboosting can lead to serious engine damage.

- Engine Speed (RPM): This is your baseline. Everything else is related to RPM.

- Throttle Position (TPS): How much the throttle is open. Gives you an idea of engine load.

- Ignition Timing: The angle (in degrees before top dead center - BTDC) at which the spark plug fires. Crucial for power and preventing knock. More timing generally equals more power, but too much timing leads to detonation.

- Knock Retard: This shows how much the ECU is pulling timing due to detected knock. Knock is extremely bad for your engine, so any knock retard is a red flag.

- Intake Air Temperature (IAT): The temperature of the air entering your engine. Hotter air is less dense, reducing power and increasing the risk of knock. Intercoolers help keep IATs down.

- Coolant Temperature (ECT): The temperature of your engine coolant. Overheating is a major engine killer.

- Fuel Injector Duty Cycle: The percentage of time the fuel injectors are open. A high duty cycle (close to 100%) indicates the injectors are running out of capacity.

Data Logging Software: Choosing the Right Tool for the Job

The software you use to log data is just as important as the parameters you monitor. There are many options available, each with its own strengths and weaknesses. Here are a few popular choices:

- ECU-Specific Software: Many aftermarket ECUs (like those from Haltech, AEM, or Hondata) come with their own proprietary logging software. These are usually the best option because they're designed specifically for the ECU and offer seamless integration. Examples include:

- Haltech ESP: Excellent for Haltech ECUs, offering advanced features and customization.

- AEMdata: Designed for AEM ECUs, known for its user-friendly interface and powerful analysis tools.

- Hondata FlashPro Manager: Specifically for Honda/Acura vehicles using Hondata FlashPro, providing comprehensive logging and tuning capabilities.

- OBD2 Data Loggers: These loggers connect to your vehicle's OBD2 port and can read data from the ECU. They're generally less comprehensive than ECU-specific software but can be a good option for stock ECUs or vehicles where ECU-specific software isn't available. Examples include:

- Torque Pro (Android): A popular and affordable app that connects to an OBD2 adapter and provides real-time data logging.

- OBDLink MX+: A high-quality OBD2 adapter that works with various logging apps and offers fast data rates.

- Standalone Data Loggers: These are dedicated devices that log data independently of the ECU. They often have more advanced features, such as GPS tracking and accelerometer data. Examples include:

- AIM Solo 2 DL: A popular choice for track days and racing, offering GPS-based lap timing and data logging.

Setting Up Your Data Logging Session: A Step-by-Step Guide

Okay, let's get practical. Here's how to set up a data logging session, assuming you're using ECU-specific software. The exact steps will vary depending on your software, but the general principles are the same:

- Connect to the ECU: Establish a connection between your laptop and the ECU using the appropriate cable and software.

- Select Parameters: Choose the parameters you want to log from the available list. Make sure to include the essentials we discussed earlier (AFR/Lambda, MAP, RPM, Timing, etc.).

- Set Logging Rate: The logging rate determines how frequently data is recorded. A higher logging rate (e.g., 10 Hz or 10 samples per second) provides more detailed data but also creates larger files. A good starting point is 5-10 Hz for most parameters. You might want to increase the rate for fast-changing parameters like knock retard.

- Configure Logging Triggers (Optional): Some software allows you to set triggers that automatically start or stop logging based on certain conditions (e.g., when RPM exceeds a certain value, or when boost pressure reaches a certain level). This can be useful for capturing specific events.

- Start Logging: Begin recording data while you perform your tuning runs.

- Save the Log File: Once you've completed your runs, save the log file in a format that can be easily analyzed (e.g., CSV).

Data Analysis: Making Sense of the Numbers

Collecting data is only half the battle. Now you need to analyze it and figure out what it's telling you. This is where things get interesting. Here are some key things to look for:

- AFR/Lambda Deviations: Are you running too lean (AFR too high) or too rich (AFR too low) at any point in the RPM range or under boost? Adjust your fuel map accordingly.

- Knock Retard: Is the ECU pulling timing due to knock? If so, reduce timing in those areas of the map, or investigate other potential causes of knock (e.g., high IATs, low octane fuel).

- Boost Spikes or Droop: Is your boost pressure stable and consistent, or is it spiking or dropping off at certain RPMs? Adjust your boost control settings to optimize boost response.

- Injector Duty Cycle: Are your injectors running out of capacity? If so, you'll need to upgrade to larger injectors.

- IAT Spikes: Are your intake air temperatures getting too high? If so, you may need to upgrade your intercooler or improve airflow to the intercooler.

Data Logging in Different Scenarios: Street Tuning, Dyno Tuning, and Track Days

The way you approach data logging will vary depending on the tuning environment:

- Street Tuning: Street tuning involves logging data while driving on public roads. This can be convenient, but it's also more challenging and potentially dangerous. Be sure to choose safe locations for your tuning runs and always prioritize safety. Consider having a passenger operate the laptop while you focus on driving. Focus on logging data during typical driving conditions (e.g., cruising, accelerating, and decelerating).

- Dyno Tuning: Dyno tuning involves logging data while the vehicle is running on a dynamometer. This is a more controlled environment than street tuning, allowing you to perform repeatable runs and make precise adjustments. A dyno also allows you to simulate different load conditions and RPM ranges. Focus on logging data during steady-state pulls at different RPMs and throttle positions.

- Track Days: Track days offer a unique opportunity to log data under extreme conditions. Focus on logging data during different sections of the track (e.g., straights, corners, and braking zones). Pay attention to parameters like brake temperature, coolant temperature, and oil pressure.

Troubleshooting Data Logging Issues: Common Problems and Solutions

Sometimes things don't go as planned. Here are some common data logging issues and how to fix them:

- Connection Problems: Ensure the cable is properly connected to both the laptop and the ECU. Check the ECU's power supply and ground connections. Verify that the software is compatible with the ECU.

- Missing Parameters: Make sure the parameters you want to log are supported by the ECU and the logging software. Some parameters may require additional sensors or modules.

- Inaccurate Data: Check the calibration of your sensors. Ensure the sensors are properly installed and functioning correctly. Look for any signs of wiring issues or electrical interference.

- Slow Logging Rate: Reduce the number of parameters being logged. Upgrade to a faster logging device or software. Close any unnecessary programs running on your laptop.

Product Recommendations: Data Logging Hardware and Software

To make your data logging experience even better, consider these products:

- Wideband O2 Sensor Kit: A wideband O2 sensor is essential for accurate AFR/Lambda readings. The Innovate Motorsports MTX-L Plus is a popular and reliable option, costing around $200. Its digital display makes it easy to monitor AFR in real-time.

- OBD2 Data Logger: The OBDLink MX+ ($140) is a fast and reliable OBD2 adapter that's compatible with various logging apps. It supports both Android and iOS devices.

- ECU Tuning Software: If you're using an aftermarket ECU, invest in a good tuning software package. Haltech ESP and AEMdata are both excellent choices, but they can be expensive (ranging from $500 to $1500 depending on the ECU).

Comparing Data Loggers: Features, Price, and Performance

Choosing the right data logger can be tough. Here's a quick comparison of some popular options:

| Data Logger | Features | Price | Pros | Cons |

|---|---|---|---|---|

| Innovate Motorsports MTX-L Plus | Wideband O2 sensor, digital display | $200 | Accurate AFR readings, easy to install | Limited to AFR data |

| OBDLink MX+ | OBD2 data logging, Bluetooth connectivity | $140 | Fast data rates, compatible with various apps | Limited by OBD2 data availability |

| Haltech ESP | ECU-specific logging, advanced features | $500 - $1500 (with ECU) | Seamless integration, comprehensive data | Expensive, only works with Haltech ECUs |

Real-World Examples: Tuning with Data Logs

Let's look at a couple of real-world examples to illustrate how data logs can be used to improve engine performance:

- Example 1: Lean Condition Under Boost: A data log reveals that the engine is running lean (AFR above 13:1) under boost. This could be caused by insufficient fuel delivery. The solution is to increase fuel in the affected areas of the fuel map, or upgrade to larger fuel injectors.

- Example 2: Knock Retard at High RPM: A data log shows that the ECU is pulling timing due to knock at high RPM. This could be caused by excessive ignition timing, high IATs, or low octane fuel. The solution is to reduce timing in the affected areas of the ignition map, improve cooling, or use higher octane fuel.

Mastering data logging is an ongoing process. The more you practice and experiment, the better you'll become at interpreting the data and making informed tuning decisions. So, get out there, start logging, and unlock the full potential of your engine!

:max_bytes(150000):strip_icc()/277019-baked-pork-chops-with-cream-of-mushroom-soup-DDMFS-beauty-4x3-BG-7505-5762b731cf30447d9cbbbbbf387beafa.jpg)