How to Read and Interpret Engine Data Logs for Tuning

Unlock the secrets hidden within your engine's data. Learn how to read and interpret data logs to identify areas for improvement and fine-tune your engine for optimal results. Master the art of data-driven tuning.

Understanding Engine Data Logs The Foundation of Data Driven Tuning

Alright, so you're serious about tuning your engine, huh? Ditching the guesswork and going straight for the data is the smartest move you can make. But staring at a spreadsheet full of numbers can be intimidating. Don't sweat it! We’re going to break down how to read and interpret engine data logs, turning you from a novice into a data-driven tuning guru. Think of data logs as your engine's diary, recording everything it's doing in real-time. It tells you the truth, the whole truth, and nothing but the truth (well, as long as your sensors are accurate!). The trick is learning how to decipher this diary and use it to make informed decisions about your tuning adjustments.

What exactly IS an engine data log? It's a recording of various engine parameters over time. These parameters are measured by sensors and recorded by your ECU or a separate data logging device. The file format is often CSV (Comma Separated Values), which can be easily opened in spreadsheet software like Microsoft Excel, Google Sheets, or specialized data analysis tools.

Key Parameters to Monitor When Reading Engine Data Logs for Optimal Tuning

Before you get lost in a sea of numbers, let's focus on the key parameters you absolutely *need* to understand. These are the bread and butter of engine data analysis, giving you the most bang for your buck.

- RPM (Revolutions Per Minute): This is your engine's heartbeat. It tells you how fast the crankshaft is spinning. Crucial for understanding where in the powerband you are.

- Engine Load: How hard the engine is working. Measured in various ways (MAF, MAP, throttle position), it's a key indicator of fuel demand.

- MAF (Mass Airflow) or MAP (Manifold Absolute Pressure): MAF measures the mass of air entering the engine directly. MAP measures the pressure in the intake manifold. Choose the appropriate one based on your engine setup.

- Throttle Position (TPS): How far open the throttle is. Directly related to driver input and engine load.

- Air-Fuel Ratio (AFR) or Lambda: The ratio of air to fuel in the combustion chamber. *Critically* important for performance and engine health. You want to aim for specific AFR targets depending on the engine load and RPM.

- Ignition Timing: How many degrees before top dead center (BTDC) the spark plug fires. This has a HUGE impact on power and knock.

- Knock Retard: How much the ECU is pulling timing due to detected knock. This is a warning sign! You need to address the cause of the knock.

- Intake Air Temperature (IAT): The temperature of the air entering the engine. Hotter air is less dense, reducing power.

- Coolant Temperature (ECT): The temperature of the engine coolant. Overheating is a major problem!

- Fuel Injector Duty Cycle: The percentage of time the fuel injectors are open. If you're exceeding 80-85%, you need larger injectors.

- Boost Pressure (for Turbocharged/Supercharged Engines): The pressure in the intake manifold above atmospheric pressure. Key for understanding turbo/supercharger performance.

Setting Up Your Data Logging System Software and Hardware Recommendations

Okay, you know what to look for, but how do you actually *get* the data? You'll need a data logging system. This typically involves a combination of hardware and software.

- OBD2 Scanner/Data Logger: These plug into your car's OBD2 port and can read and record data from the ECU. There are countless options available, from basic handheld scanners to more advanced units with built-in displays and logging capabilities.

- Standalone Data Logger: These are more advanced units that connect directly to your engine sensors, bypassing the ECU. They offer higher sampling rates and the ability to log more parameters. Often used in racing applications.

- ECU with Built-in Data Logging: Many aftermarket ECUs have built-in data logging capabilities. This is often the most convenient option, as it's integrated directly into the ECU software.

- Laptop/Tablet: You'll need a laptop or tablet to run the data logging software and analyze the data.

Product Recommendations:

- For Beginners (OBD2 Scanners):

- BlueDriver Bluetooth Professional OBDII Scan Tool: Easy to use, Bluetooth connectivity, works with iOS and Android. Around $120. Great for monitoring basic parameters and reading/clearing codes.

- OBDLink MX+: Fast, reliable, and supports a wide range of vehicles. Offers advanced features like live data streaming and custom PIDs. Around $140.

- For Enthusiasts (Standalone Data Loggers):

- AEM Electronics CD-7 Digital Dash Display: A full-featured digital dash with built-in data logging. Expensive (around $1500), but offers a professional-level solution. Ideal for track cars.

- Race Technology DL1 MK3: A powerful and versatile data logger for motorsport applications. Supports a wide range of sensors and offers advanced data analysis tools. Price varies depending on configuration.

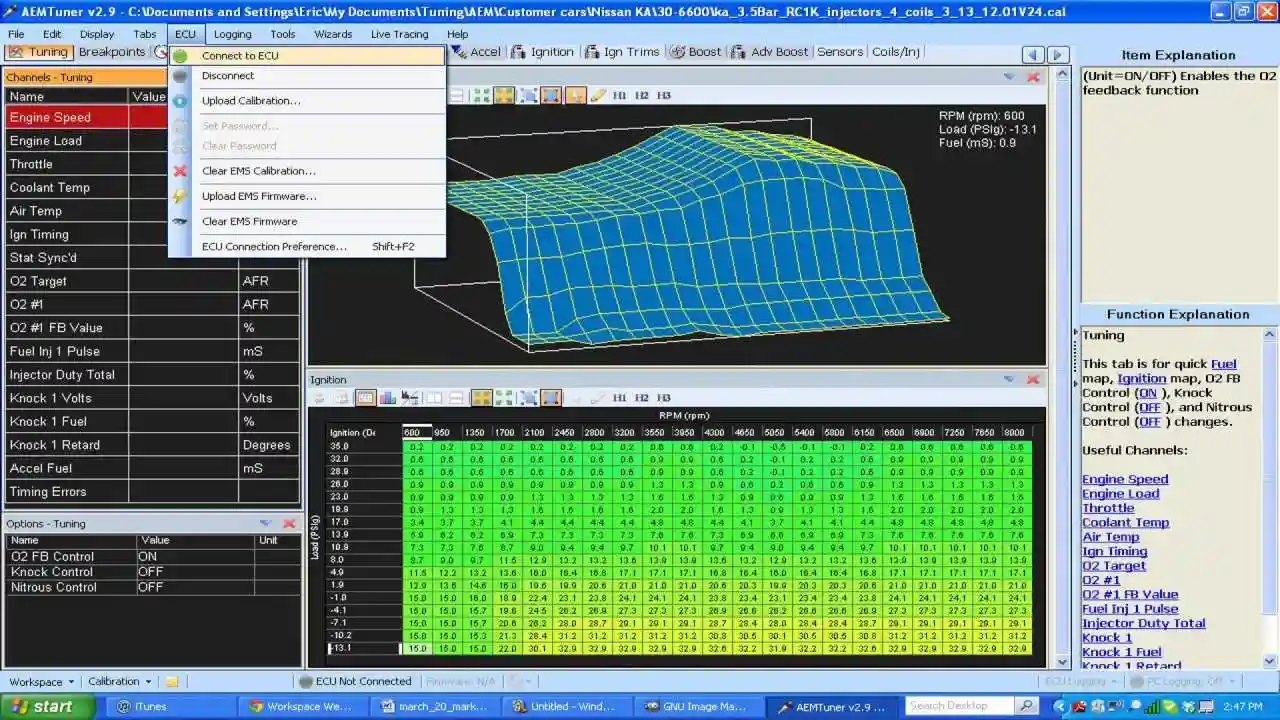

- For ECU-Based Logging:

- Haltech Elite Series: Aftermarket ECUs with excellent logging capabilities. Price depends on the specific ECU model.

- Megasquirt MS3Pro: A popular DIY ECU with robust data logging features. More affordable than Haltech, but requires more technical knowledge to set up.

Software Recommendations:

- Excel/Google Sheets: Good for basic data analysis and visualization.

- MegaLogViewer HD: Free software specifically designed for analyzing Megasquirt data logs.

- DataLog Lab: Powerful data analysis software with advanced features like channel math and automatic event detection. Paid software, but offers a free trial.

Analyzing Your Engine Data Log Identifying Trends and Anomalies

Now for the fun part! Open your data log in your chosen software. You'll see a spreadsheet-like display with columns representing the different parameters and rows representing the data points recorded over time. The key is to visualize this data to identify trends and anomalies.

- Graphing: This is your best friend. Plot the key parameters (RPM, AFR, timing, boost) against time. Look for smooth curves and consistent behavior. Spikes, dips, or sudden changes are red flags.

- Scatter Plots: Plot one parameter against another (e.g., AFR vs. RPM). This can reveal relationships that are not obvious in a time-based graph.

- Channel Math: Create new channels by performing mathematical operations on existing channels. For example, you could calculate horsepower based on MAF and RPM.

Example Scenario:

Let's say you're analyzing a data log from a dyno pull. You notice that your AFR is leaning out (becoming more lean) at high RPM. This could indicate that your fuel injectors are running out of capacity, or that you have a fuel delivery problem. You also notice that your knock retard is increasing at the same time. This is a dangerous situation! The lean AFR is causing knock, and the ECU is pulling timing to protect the engine. You need to address the lean condition before continuing to tune.

Common Engine Data Log Problems and Solutions Troubleshooting Techniques

Data logging isn't always perfect. You might encounter problems like missing data, inaccurate readings, or noisy signals. Here are some common issues and how to troubleshoot them:

- Missing Data: Check your sensor connections and make sure the sensor is functioning properly.

- Inaccurate Readings: Calibrate your sensors and verify their accuracy with a known standard.

- Noisy Signals: Use shielded wiring and proper grounding techniques to reduce electrical noise.

- Sampling Rate Too Low: Increase the sampling rate of your data logger to capture more data points per second. This is especially important for fast-transient events like knock.

- Sensor Failure: Replace the faulty sensor.

Real World Applications of Engine Data Log Analysis Tuning for Specific Scenarios

The beauty of data logging is that you can use it to tune your engine for specific scenarios. Here are a few examples:

- Street Tuning: Use data logs to optimize your fuel and timing maps for everyday driving conditions. Focus on fuel economy, drivability, and smooth power delivery.

- Track Tuning: Use data logs to optimize your engine for maximum power and performance on the track. Focus on high-RPM power, consistent AFR, and knock control.

- Drag Racing: Use data logs to optimize your engine for the quarter-mile. Focus on launch control, boost control, and maximizing power throughout the run.

- Troubleshooting: Use data logs to diagnose engine problems. Look for anomalies in the data that might indicate a faulty sensor, a fuel delivery problem, or a vacuum leak.

Data Log Examples and Interpretation Step-by-Step Analysis

Let's walk through a couple of example data logs to illustrate the process of data analysis.

Example 1: Identifying a Boost Leak

You're experiencing lower-than-expected boost pressure. You log boost pressure, RPM, and throttle position. You notice that boost pressure peaks lower than your target and then slowly drops off at higher RPM, even though the throttle is fully open. This is a classic sign of a boost leak. The leak is preventing the turbo from building full boost, and the pressure is dropping off as the engine demands more air.

Solution: Pressure test your intake system to identify the leak. Common leak locations include intercooler connections, throttle body gaskets, and vacuum lines.

Example 2: Tuning for E85 Fuel

You've converted your engine to run on E85 fuel. You log AFR, ignition timing, and knock retard. You start by richening the fuel mixture compared to gasoline. You then gradually increase ignition timing, while carefully monitoring knock retard. You find that you can run significantly more timing on E85 without knock, resulting in a noticeable power increase.

Solution: Continue to fine-tune the fuel and timing maps to maximize power while maintaining a safe AFR and avoiding knock.

Advanced Data Logging Techniques Closed Loop Control and More

Once you've mastered the basics, you can explore more advanced data logging techniques, such as:

- Closed-Loop Control: Use data logs to fine-tune your PID (Proportional, Integral, Derivative) controllers for closed-loop systems like boost control and idle control.

- Sensor Calibration: Use data logs to calibrate your sensors for maximum accuracy.

- Modeling and Simulation: Use data logs to create models of your engine's behavior. These models can be used to simulate different tuning scenarios and predict the results.

Interpreting engine data logs is a continuous learning process. The more you practice, the better you'll become at identifying trends, diagnosing problems, and optimizing your engine's performance. So get out there, start logging, and unlock the hidden potential of your engine!

:max_bytes(150000):strip_icc()/277019-baked-pork-chops-with-cream-of-mushroom-soup-DDMFS-beauty-4x3-BG-7505-5762b731cf30447d9cbbbbbf387beafa.jpg)