ECU Mapping for Turbocharged vs. Naturally Aspirated Engines

Turbocharged and naturally aspirated engines require different ECU mapping strategies. This guide covers the specific considerations for each type of engine, including boost control, ignition timing, and fuel delivery. Optimize your tuning for your engine's configuration.

Understanding the Fundamental Differences Turbo vs NA Engines

Alright, let's dive into the nitty-gritty of ECU mapping for turbocharged (turbo) versus naturally aspirated (NA) engines. These two engine types are fundamentally different in how they generate power, which means their ECU mapping needs a completely different approach. A naturally aspirated engine relies solely on atmospheric pressure to fill its cylinders with air, while a turbocharged engine forces air into the cylinders using a turbine powered by exhaust gases. This forced induction creates significantly higher cylinder pressures and requires precise control of fuel, ignition, and boost.

Think of it like this: an NA engine is like breathing normally, while a turbo engine is like breathing through a ventilator. The ventilator (turbocharger) forces more air in, but if the settings aren't right, things can go south pretty quickly. That’s where ECU mapping comes in – it’s the doctor fine-tuning the ventilator settings to make sure everything runs smoothly and efficiently.

Fuel Delivery Strategies ECU Mapping for Optimal AFR

Fuel delivery is a critical aspect of ECU mapping for both engine types, but the strategies differ significantly. In an NA engine, fuel delivery is primarily determined by throttle position, engine speed (RPM), and manifold absolute pressure (MAP). The ECU uses these inputs to calculate the required amount of fuel and inject it into the cylinders. The goal is to maintain an optimal air-fuel ratio (AFR), typically around 14.7:1 for stoichiometric combustion (ideal for emissions and fuel economy) or slightly richer (lower ratio) for maximum power.

For a turbo engine, fuel delivery becomes much more complex. In addition to throttle position, RPM, and MAP, the ECU must also consider boost pressure. As boost pressure increases, the engine needs more fuel to maintain the correct AFR. The ECU uses a boost enrichment table to add extra fuel as boost rises. It’s crucial to get this right – too little fuel can lead to a lean condition, which can cause detonation and engine damage. Too much fuel results in poor fuel economy and potentially fouled spark plugs.

Product Recommendation: AEM Fuel/Ignition Controller. This unit is a popular choice for both NA and turbo applications, offering precise fuel and ignition control. It allows for custom fuel maps based on RPM, MAP, and boost (for turbo engines). Price: Around $1200.

Ignition Timing Considerations Advancing and Retarding Spark

Ignition timing is another crucial parameter that needs to be carefully mapped for both engine types. Ignition timing refers to the point at which the spark plug fires in relation to the piston's position. Advancing the timing means firing the spark plug earlier, while retarding the timing means firing it later. The optimal ignition timing depends on several factors, including engine speed, load, and fuel octane.

In an NA engine, ignition timing is typically advanced at lower RPMs and loads to improve throttle response and fuel economy. As RPM and load increase, the timing is gradually retarded to prevent detonation. The ECU uses a base timing table and adjusts it based on inputs from various sensors, such as the knock sensor. If the knock sensor detects detonation, the ECU will retard the timing to protect the engine.

For a turbo engine, ignition timing is even more critical. The increased cylinder pressures in a turbo engine make it more prone to detonation. Therefore, ignition timing is typically more conservative (retarded) in a turbo engine, especially at higher boost levels. The ECU uses a boost-dependent ignition timing table to retard the timing as boost increases. Again, knock control is essential to prevent engine damage. Aggressive turbo tunes require very fine ignition timing adjustments.

Product Comparison: MSD Ignition vs. AEM. MSD Ignition systems are known for their strong spark output and are popular for high-performance NA engines. AEM, on the other hand, offers more sophisticated timing control and data logging capabilities, making it a better choice for complex turbo setups. MSD Ignition systems range from $300 to $800, while AEM systems start around $1000.

Boost Control Strategies Managing Turbocharger Pressure

Boost control is unique to turbocharged engines and is one of the most important aspects of ECU mapping. Boost control refers to the ECU's ability to regulate the amount of boost pressure generated by the turbocharger. The goal is to maintain a stable and consistent boost level, prevent overboost, and optimize performance.

There are several different boost control strategies, including wastegate control, boost controllers, and electronic boost control. Wastegate control is the most basic method, where the ECU controls a valve (wastegate) that bypasses exhaust gases around the turbine, limiting boost pressure. Boost controllers are more sophisticated devices that allow for finer control of boost pressure. Electronic boost control uses a solenoid valve to precisely regulate the amount of pressure applied to the wastegate actuator.

The ECU uses a target boost table to determine the desired boost level based on RPM and throttle position. It then monitors the actual boost pressure using a MAP sensor and adjusts the boost control system to maintain the target boost. Proper boost control is essential for preventing overboost, which can damage the turbocharger or engine.

Usage Scenario: Street vs. Track. On the street, a conservative boost control strategy is recommended for reliability and fuel economy. On the track, a more aggressive boost control strategy can be used to maximize power, but it requires careful monitoring and tuning.

Airflow Management and Sensor Calibration MAF vs MAP

Both turbo and NA engines rely on accurate airflow measurement for proper ECU mapping. The most common methods are using a Mass Airflow (MAF) sensor or a Manifold Absolute Pressure (MAP) sensor. A MAF sensor directly measures the mass of air entering the engine, while a MAP sensor measures the pressure in the intake manifold. The ECU uses these measurements to calculate the amount of fuel required.

MAF sensors are typically used in NA engines, as they provide a more direct measurement of airflow. However, MAF sensors can become restrictive at higher horsepower levels. MAP sensors are more commonly used in turbo engines, as they can handle higher airflow rates and are less restrictive. However, MAP sensors require more sophisticated calibration and tuning.

Proper sensor calibration is essential for accurate ECU mapping. The ECU needs to know the exact characteristics of each sensor to correctly interpret the data. Sensor calibration involves inputting the sensor's voltage or frequency range into the ECU. This ensures that the ECU accurately calculates airflow and fuel requirements.

Knock Control Strategies Preventing Engine Damage

Knock control is a crucial safety feature in modern ECUs. Knock, also known as detonation, is an uncontrolled combustion process that can cause severe engine damage. It occurs when the air-fuel mixture ignites spontaneously due to excessive heat and pressure in the cylinder. The ECU uses a knock sensor to detect knock and retard the ignition timing to prevent damage.

The knock sensor is a piezoelectric sensor that detects vibrations in the engine block. When knock occurs, the sensor generates a signal that the ECU interprets as knock. The ECU then retards the ignition timing in that cylinder to reduce the likelihood of further knock. The amount of timing retardation depends on the severity of the knock. Some advanced ECUs also have individual cylinder knock control.

Proper knock control is essential for maximizing engine performance and reliability. Aggressive tuning strategies often push the engine close to the knock threshold, requiring precise knock control to prevent damage. It's important to use high-quality fuel and maintain a properly functioning cooling system to minimize the risk of knock.

Data Logging and Analysis Fine-Tuning Your ECU Map

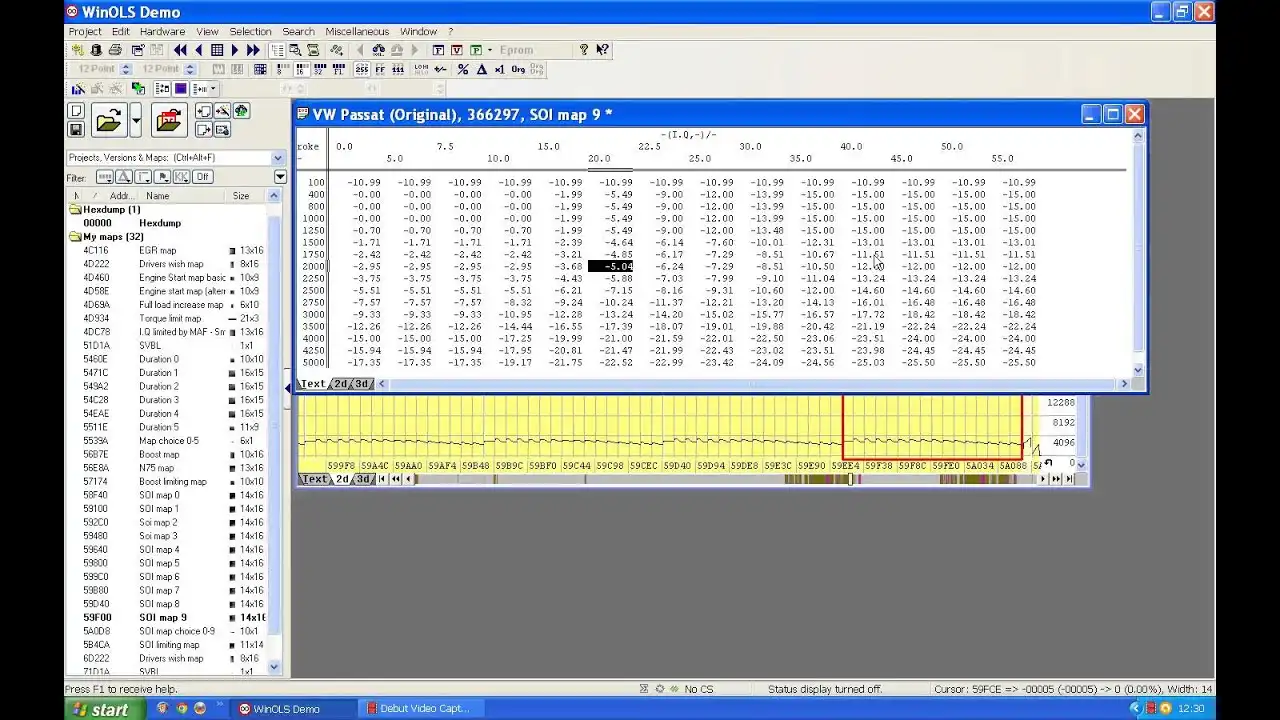

Data logging is an essential part of the ECU mapping process. Data logging involves recording various engine parameters, such as RPM, throttle position, boost pressure, AFR, and ignition timing. This data can then be analyzed to identify areas for improvement in the ECU map.

Most aftermarket ECUs have built-in data logging capabilities. The data can be downloaded to a computer and analyzed using specialized software. Data logging software allows you to graph engine parameters over time and identify trends and anomalies. This information can be used to fine-tune the ECU map for optimal performance.

For example, if the data log shows that the AFR is consistently lean at high RPMs, the fuel map can be adjusted to add more fuel in that area. Similarly, if the data log shows that knock is occurring at a certain boost level, the ignition timing can be retarded to prevent damage. Data logging is an iterative process that involves making small adjustments to the ECU map and then re-logging data to see the effects.

Product Recommendation: HP Tuners. This software and interface is a popular choice for data logging and ECU tuning, offering comprehensive data analysis tools and user-friendly interface. Price: Around $500.

Specific Parameter Adjustments for Turbo Engines PID Control

Turbocharged engines require some specific parameter adjustments in the ECU map that are not relevant to naturally aspirated engines. These include:

- Boost PID Control: PID (Proportional, Integral, Derivative) control is used to precisely regulate boost pressure. The PID controller adjusts the wastegate duty cycle to maintain the target boost level. Proper PID tuning is essential for stable and responsive boost control.

- Transient Fueling: Transient fueling refers to the extra fuel required during rapid throttle changes. Turbo engines need more transient fueling than NA engines due to the lag in boost response.

- Tip-In Enrichment: Tip-in enrichment is a short burst of fuel added when the throttle is initially opened. This helps to improve throttle response and prevent hesitation.

- Overboost Protection: Overboost protection is a safety feature that prevents the turbocharger from generating excessive boost pressure. The ECU will cut fuel or ignition if the boost exceeds a certain threshold.

Specific Parameter Adjustments for Naturally Aspirated Engines VE Table Tuning

While naturally aspirated engines don't have the complexities of boost control, they still require careful tuning of specific parameters:

- Volumetric Efficiency (VE) Table: This table represents how efficiently the engine fills its cylinders with air at different RPMs and manifold pressures. Tuning the VE table is crucial for accurate fuel delivery in NA engines.

- Idle Control: Precise idle control is important for smooth engine operation at idle. The ECU uses various strategies to maintain a stable idle speed, such as adjusting the idle air control valve.

- Throttle Response: Tuning the throttle response can improve the driving experience. This involves adjusting the throttle sensitivity and fuel enrichment to provide a more responsive feel.

Real-World Examples and Scenarios

Let's look at some real-world examples:

- Scenario 1: Tuning a Honda Civic with a turbo kit. The tuner would need to carefully map the boost control, fuel delivery, and ignition timing to handle the increased power. Data logging would be essential to identify any knock or lean conditions.

- Scenario 2: Tuning a Mazda Miata with bolt-on modifications (intake, exhaust, cams). The tuner would focus on optimizing the VE table, ignition timing, and idle control for improved throttle response and horsepower.

Choosing the Right ECU for Your Engine Type Standalone vs Piggyback

The choice of ECU is critical. There are two main types: standalone and piggyback.

- Standalone ECUs: These replace the factory ECU and offer complete control over all engine parameters. They are typically used for heavily modified engines that require advanced tuning capabilities.

- Piggyback ECUs: These work in conjunction with the factory ECU and allow you to modify certain parameters. They are typically used for milder modifications and are easier to install and tune.

For a turbo engine, a standalone ECU is often the best choice, as it provides the necessary control over boost, fuel, and ignition. For an NA engine, a piggyback ECU may be sufficient, depending on the level of modification.

Product Comparison: Haltech vs. Hondata. Haltech ECUs are known for their advanced features and flexibility, making them a popular choice for high-end turbo builds. Hondata, on the other hand, is specifically designed for Honda engines and offers a user-friendly interface and pre-loaded maps, making it a good choice for NA Honda applications. Haltech ECUs start around $1500, while Hondata systems range from $500 to $1200.

Final Thoughts: NA vs Turbo Tuning - A Summary

In summary, ECU mapping for turbo and NA engines requires different approaches. Turbo engines need precise control over boost, fuel, and ignition to handle the increased cylinder pressures. NA engines require careful tuning of the VE table, ignition timing, and idle control for improved throttle response and horsepower. Data logging is essential for both engine types to fine-tune the ECU map for optimal performance and reliability. Choose the right ECU and tuning strategy for your specific engine and modifications to achieve the best results.

:max_bytes(150000):strip_icc()/277019-baked-pork-chops-with-cream-of-mushroom-soup-DDMFS-beauty-4x3-BG-7505-5762b731cf30447d9cbbbbbf387beafa.jpg)